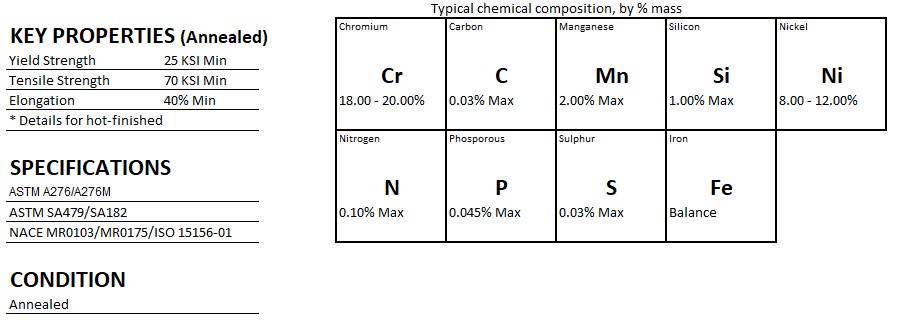

Description

Austenitic Stainless Steel Bars

WHAT ARE AUSTENITIC STAINLESS STEELS?

Austenitic stainless steels are characterized by their high nickel and chromium content. This contributes greatly to their formability, corrosion and wear resistance against the elements of nature.

Originally, austenitic stainless steel started off in 1940s with the development of the 200 series stainless steel with a higher Nitrogen content but with a lower Nickel due to the high cost back then. Fast forwarding to the present, the most common grade of Austenitic stainless steel now is the 300 series stainless steel such as grade 304 and 316 which are the two most popular grades world-wide.

AVAILABLE TYPES

QUALITY ASSURANCE

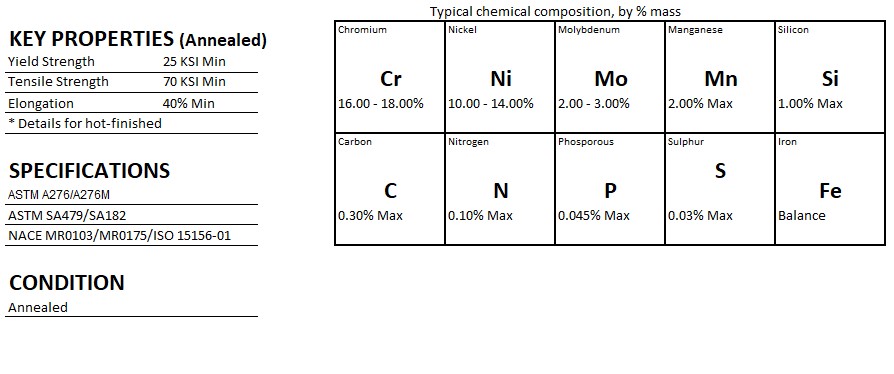

SS 316/316L (UNS S31600/S31603)

Stainless steel 316 is the 2nd most popular grade after Stainless Steel 304. The key defining difference between the two is the addition of Molybdenum. The addition of Molybdenum greater increases the corrosion resistance of grade 316 materials, hence its widespread use in outdoors and in the marine industry.

SS 310S (UNS S31008)

Stainless Steel 310 is known for its high corrosion resistance and strength in high working temperatures. It has very good oxidation resistance in general and good oxidation resistance in mildly cyclic conditions that is best employed in temperatures up to 1050°C/1920°F.

This is commonly used in heat exchange systems, furnace equipment and other high temperature usage conditions.

NITRONIC 50 / XM-19 (UNS S20910)

Nitronic 50 / XM-19 is a manganese alloyed austenitic steel with improved corrosion resistance as compared to grade 316L. Due to the increase in chromium content, this puts it at around double the yield strength of 316L at room temperature conditions. Unlike many austenitic alloys, Nitronic 50 is capable of retaining low magnetic permeability even after exposure to sub-zero temperatures or severe cold working conditions. Nitronic 50 has excellent resistance to sulfide stress cracking and intergranular attack.