Description

Stainless Steel Pipes

Stainless Steel Round Bar, Channel Bar, Beam Bar Supplier in Singapore, Malaysia, Thailand, Philippines, Indonesia

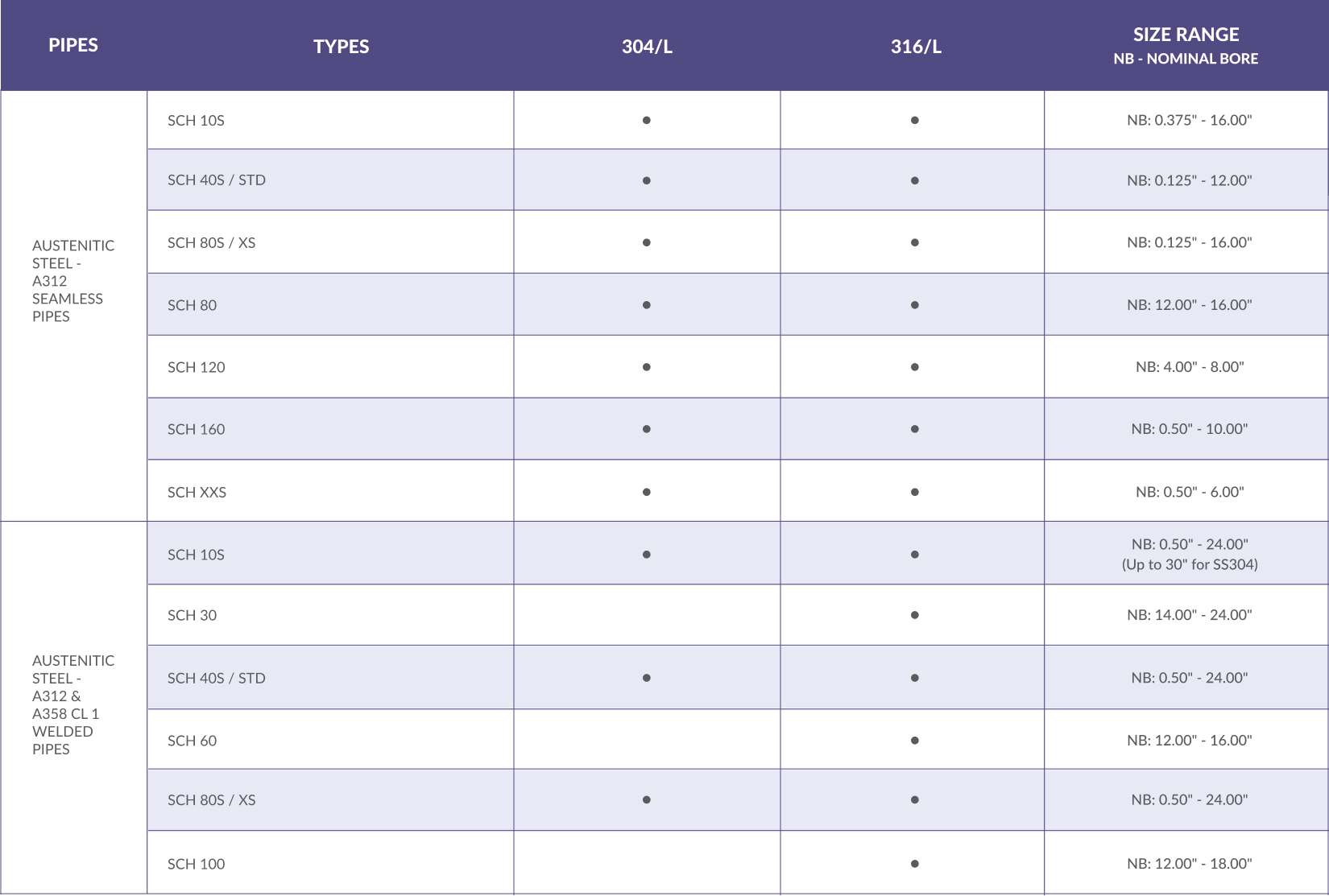

A312 & A358 STAINLESS STEEL PIPES

ASTM A312 governs the specification that covers both seamless and welded stainless steel pipes that are used for high temperature and/or corrosive service. In terms of dimensions, it would be referenced to ASME B36.10 and ASME B36.19. The standard ASME dimensional charts will show the typical combinations of pipe nominal size (NB) and wall thickness (Schedule Rating) that is available in the market. There are also sizes outside of the chart range that can be produced on special request.

A312 Welded pipes are manufactured by cold-forming a flat sheet of stainless steel into a cylindrical shape and then finally joint on the extremities on both ends electrically via a process know as electric fusion weld. The welding seam will be visible in the inner surface of the pipe itself.

A312 Seamless pipes on the other hand are manufactured from stainless steel billets. In simplified terms, the billet is heated and then perforated to create the seamless pipe. Seamless pipes as the name implies, refers to the absence of a welding seam.

Along the years, with advancement of technology, so has the methodologies for welding been improving with improvements made along the way to reduce the technical superiority of seamless pipes versus ERW pipes. In some cases, EFW pipes might provide a suitable substitute to seamless pipes in applications that have low to medium pressure and temperature. One such is the A358 Class 1 specification which employs a double weld using filler metal together with a 100% radiography test of their weld seam to detect any defects during production.

WELDED PIPE VERSUS SEAMLESS PIPE

We often hear the question of “should I use a welded or seamless pipe?”. Although that is a question for your engineering team, we can look at certain general pros and cons for each usage:

WELDED PIPES PROS AND CONS:

- Welded pipes are cheaper compared to seamless pipes. A common size would typically see around a 50% difference in terms of pricing between the two.

- Shorter lead times due to easier production methods and larger base of manufacturers

- Presence of a welding seam constitutes might prove as a weakness factor for mid to high pressure pipelines.

SEAMLESS PIPES PROS AND CONS:

- Seamless pipes are manufactured from a solid block of stainless steel and thus, do not have a welding seam

- Longer deliveries and a much higher cost are associated with the use of seamless pipes. Seamless pipes usually have extensive testing and manufacturing requirements as compared to welded pipes.

- Varying wall thicknesses due to the standard tolerance of +/- 12.5%.